Skip to content

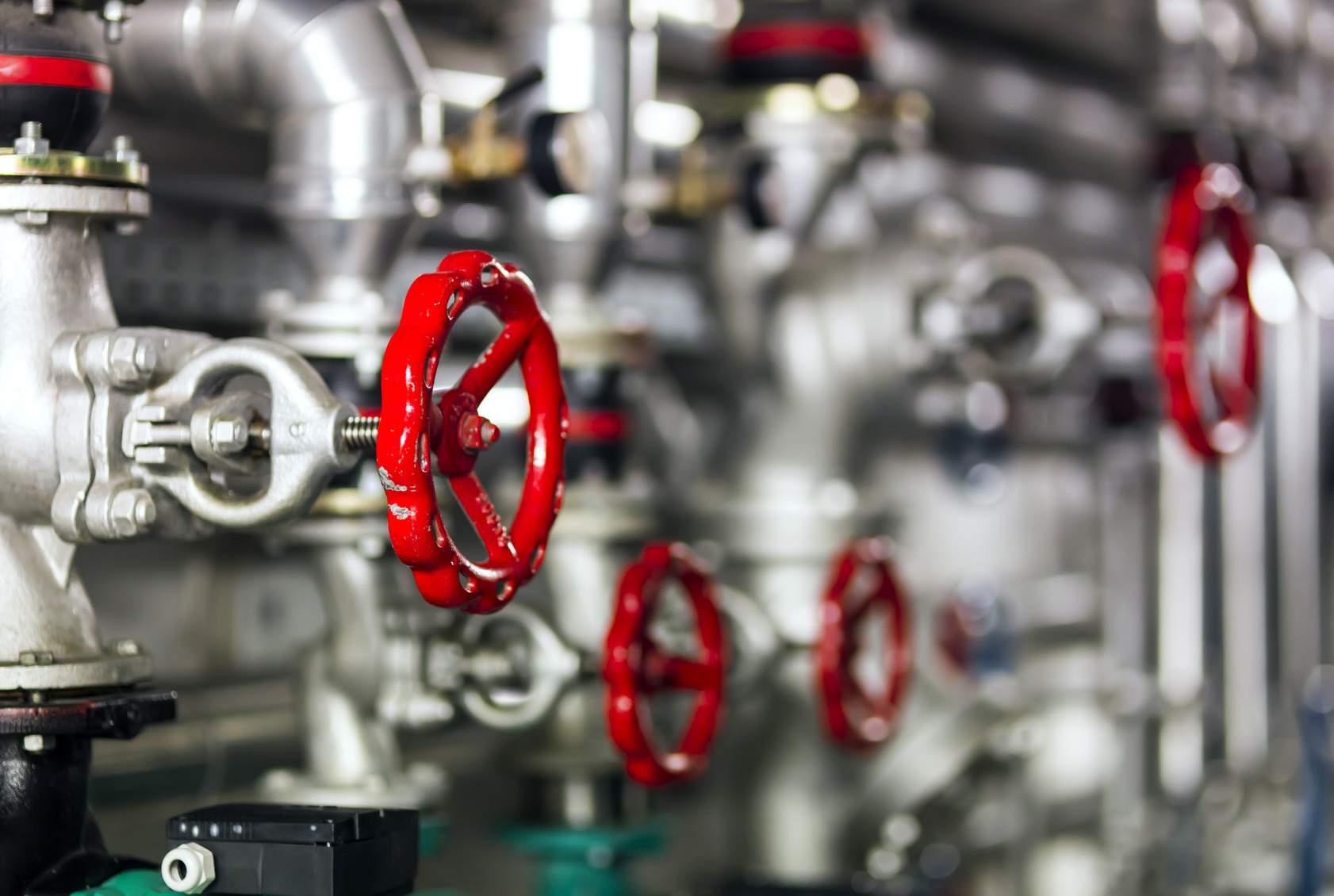

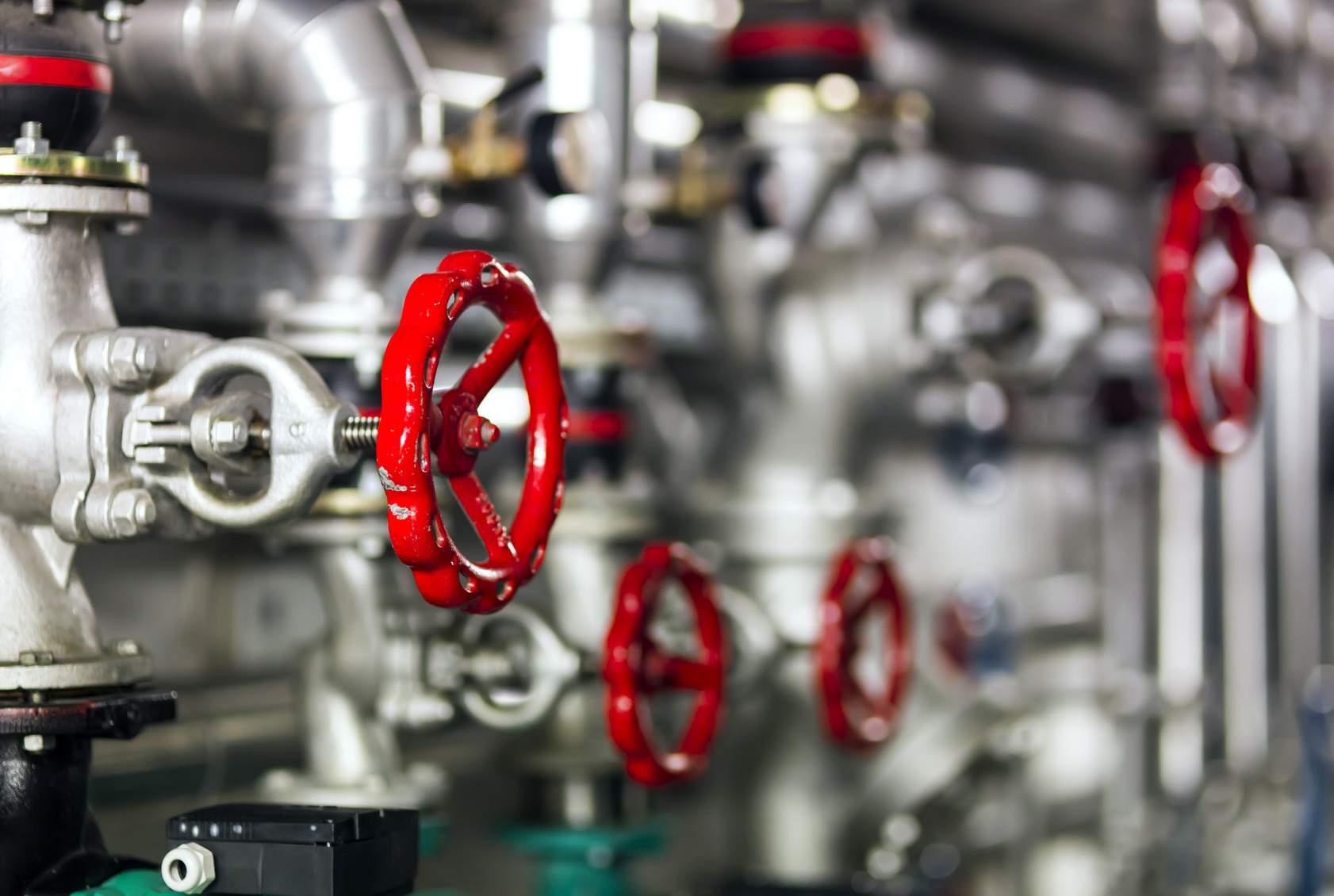

Dedicated solution based on the BES-151 HMI controller for controlling heat nodes

Ready-to-install wall-mounted control cabinet with IP66 protection

Basic features and benefits:

- On-line communication with the SCADA server (Ethernet, GSM/GPRS)

- Upgrade of firmware, control software, configuration, and process parameters via FTP server

- Electronic object identifier and software/configuration backup ensuring automatic restart of the controller with the current parameters after service replacement of the device or SIM card

- Upgrade of firmware, control programs, and process parameters using an SD card

- Support for wireless sensors of internal temperature in the building

- Remote configuration of the controller operating parameters using the SCADA application

- Ability to define schedules for superior, periodic correction of central heating and warm water parameters from the SCADA application level

- Resistance to loss of measurement data of the heat node thanks to the use of a built-in recorder

- Reading the measurement data of heat meters using M-BUS

- The possibility of expanding the measurement functions thanks to the built-in Modbus RTU and TCP protocols

- Cooperation with control valves controlled by 24 V, 230 V, -10/+10 VDC, 4-20 mA signals

Available algorithms:

- PID control of 2 central heating circuits,

- PID control of 2 DHW circuits,

- Warm water priority,

- Warm water disinfection,

- Automatic activation and deactivation of the central heating circuit depending on the outside temperature,

- Stabilization of the temperature of the thermal medium return from the node

- Correction of temperatures in central heating and domestic hot water circuits according to the controller’s fixed local schedules

- Correction of central heating parameters due to the radio sensors of internal temperature

- Manual (service) control of the position of the control valves and circulation pumps from the built-in operator panel